SWARCOFORCE glass filler beads as a filler and reinforcing material in plastics

In the plastics industry, SWARCOFORCE glass filler beads from SWARCO Indusferica are an important filler and reinforcing material. In thermoplastics, they are incorporated through compounding. Here, the purpose is primarily to optimize mechanical properties, such as rigidity, pressure resistance, heat deflection, and many other attributes.

Enhanced properties of materials

Improved scratch resistance

Improved abrasion resistance

Optimized rigidity and pressure resistance

Better heat deflection

Reduced warpage and shrinkage behaviour

Enhanced haptics

Higher surface quality

Used as anti-blocking agents

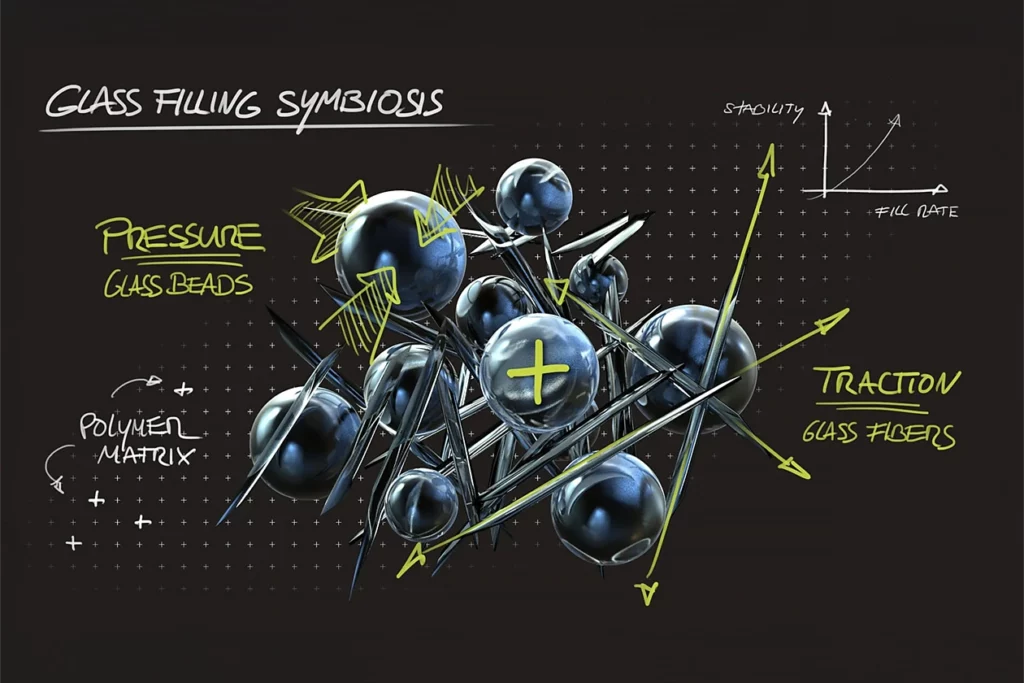

Hybrid combinations to reduce warpage

In plastic compounds, special hybrid combinations of glass fibres and glass beads are used to increase rigidity and reduce the plastic’s tendency to warp. Injection moulding materials also benefit from less warpage, as well as reduced shrinkage, the prevention of sink marks and shorter cycle times. When used in technical components, automotive parts, and 3D printed materials, this is particularly essential.

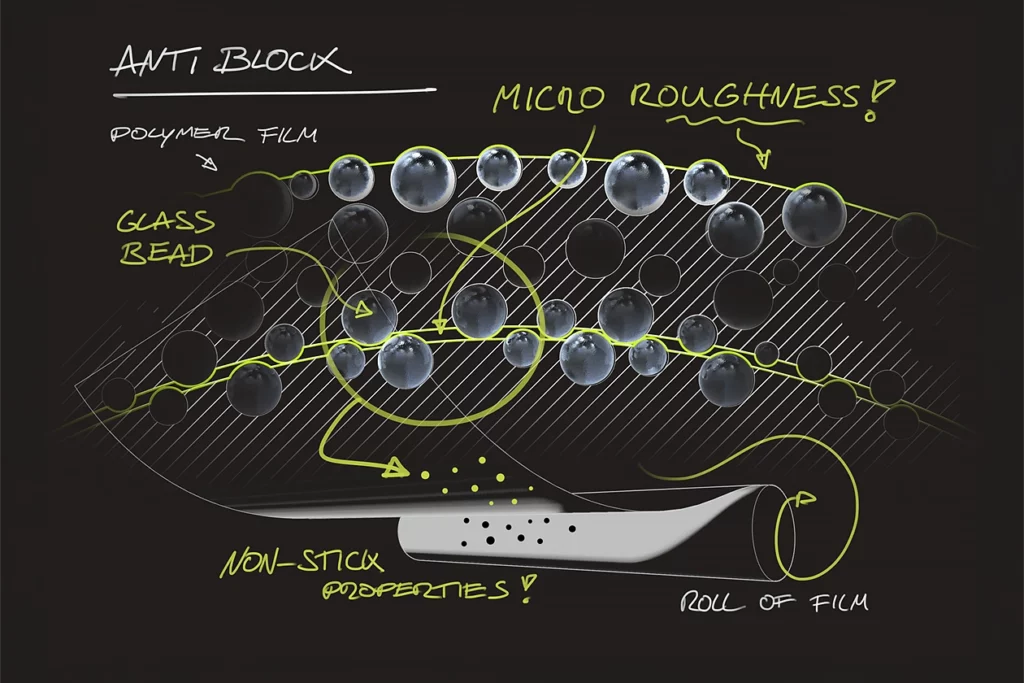

Glass filler beads as anti-blocking agents

Films, especially polyolefin films, tend to stick together or adhere to metal surfaces. Anti-blocking agents reduce this effect, enhance slip characteristics and improve winding behaviour, making this another ideal area of application for SWARCOFORCE glass filler beads.

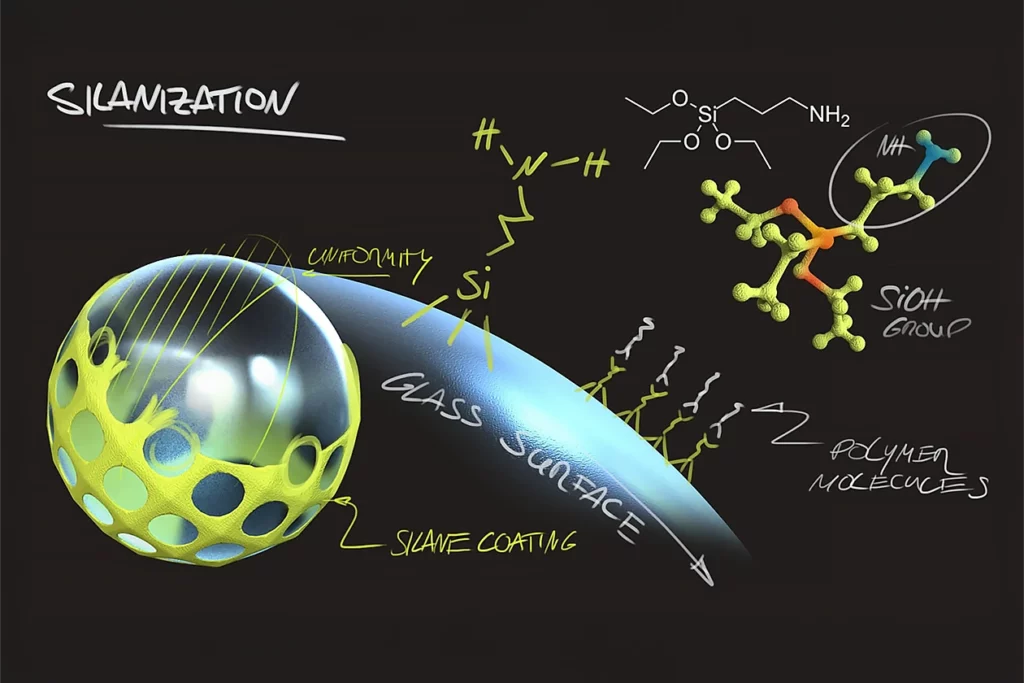

Silanization of glass filler beads

SWARCOFORCE glass filler beads can be customized with a broad range of coatings. This defines the interaction between the glass and the matrix material used. Glass filler beads modified in this way make it possible to considerably improve the final properties of the plastic.

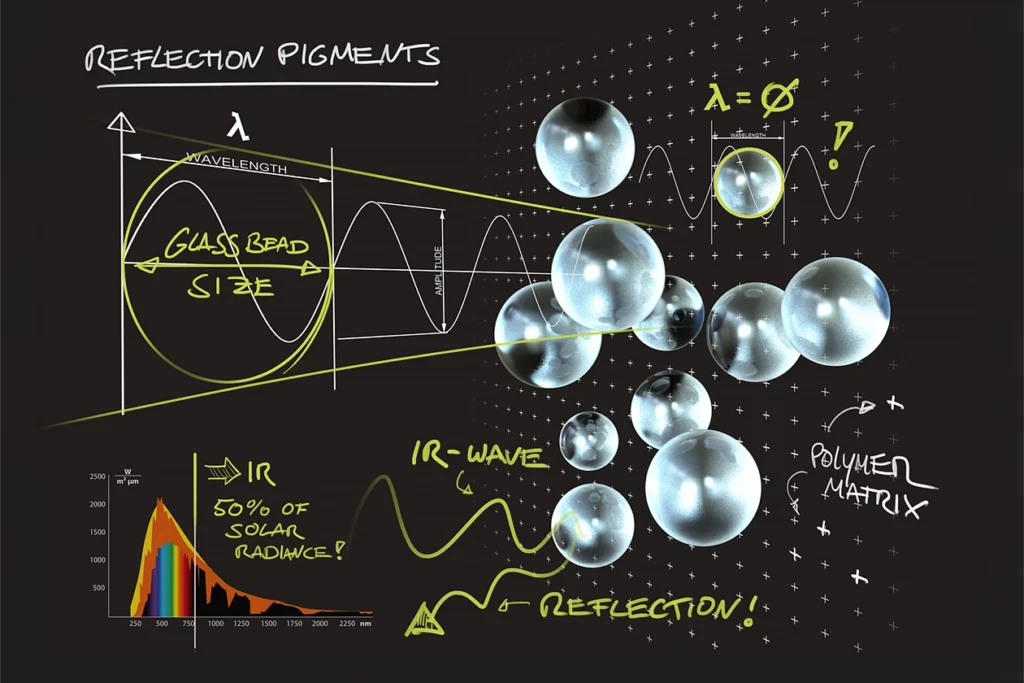

Optical properties

Glass filler beads with a high refractive index are ideal for use in plastic films and multi-wall sheets, making this a perfect area of application for SWARCOFORCE REFLEX. The glass filler beads prevent overheating during the day and reduce heat loss at night, which is ideal for greenhouses, for example, or other areas protected from the sun. Furthermore, by scattering the light, glass filler beads can create diffuse light conditions while hardly lowering transparency.

Customized solutions tailored to clients’ needs

SWARCO Indusferica is your competent partner for tailor-made solutions using micro glass beads as fillers in industrial applications. Particle-size distribution, silanization properties and filler content all influence the properties of the final product. By precisely analyzing these ratios and their effects, it is possible to optimize products in a targeted manner and develop them further. Many different grain sizes are available, and the production process ensures narrow tolerance ranges. Customized particle-size distributions are possible upon request and can be precisely tailored to clients’ needs.

PDS SWARCOFORCE 1-20

PDS SWARCOFORCE 1-20 C1

PDS SWARCOFORCE 1-20 C2

PDS SWARCOFORCE 1-20 C3

PDS SWARCOFORCE 1-50 Typ 1 C2

PDS SWARCOFORCE 1-50 Typ 1 C1

PDS SWARCOFORCE 1-50 Typ 1

PDS SWARCOFORCE 1-50 Typ 1 C3

PDS SWARCOFORCE 1-50 Typ 2 C1

PDS SWARCOFORCE 1-50 Typ 2

PDS SWARCOFORCE 1-50 Typ 2 C2

PDS SWARCOFORCE 1-50 Typ 2 C3

PDS SWARCOFORCE 40-70 C3

PDS SWARCOFORCE 40-70 C2

PDS SWARCOFORCE 40-70 C1

PDS SWARCOFORCE 40-70

PDS SWARCOFORCE 63-250

PDS SWARCOFORCE 63-250 C1

PDS SWARCOFORCE 63-250 C2

PDS SWARCOFORCE 63-250 C3

PDS SWARCOFORCE 70-110

PDS SWARCOFORCE 70-110 C1

PDS SWARCOFORCE 70-110 C2

PDS SWARCOFORCE 70-110 C3

PDS SWARCOFORCE 90-150 C2

PDS SWARCOFORCE 90-150 C1

PDS SWARCOFORCE 90-150

PDS SWARCOFORCE 90-150 C3

SWARCOFORCE Brochure

SWARCOFORCE Flyer

SWARCOFORCE Technical Information

SWARCOFORCE REFLEX Flyer

SWARCOFORCE REFLEX Technical Information

Sustainability & responsibility

At SWARCO, corporate responsibility to the environment and society plays an important role. That’s also why we take numerous steps to reduce our ecological footprint.

Glass beads with a small carbon footprint

Setting new standards in environmental compatibility

Cradle-to-Gate

An efficient circular economy

Contact us

We strive to offer our customers tailor-made solutions to meet their specific needs.

Andreas Krenmayr

Key Account Manager SWARCOFORCE