The game-changing industry system

SWARCOFORCE glass filler beads enhance the functionality of materials

SWARCOFORCE glass filler beads are a high-quality filler material that specifically improves the physical properties of plastics, resins, paints, varnishes, surface coatings and building materials.

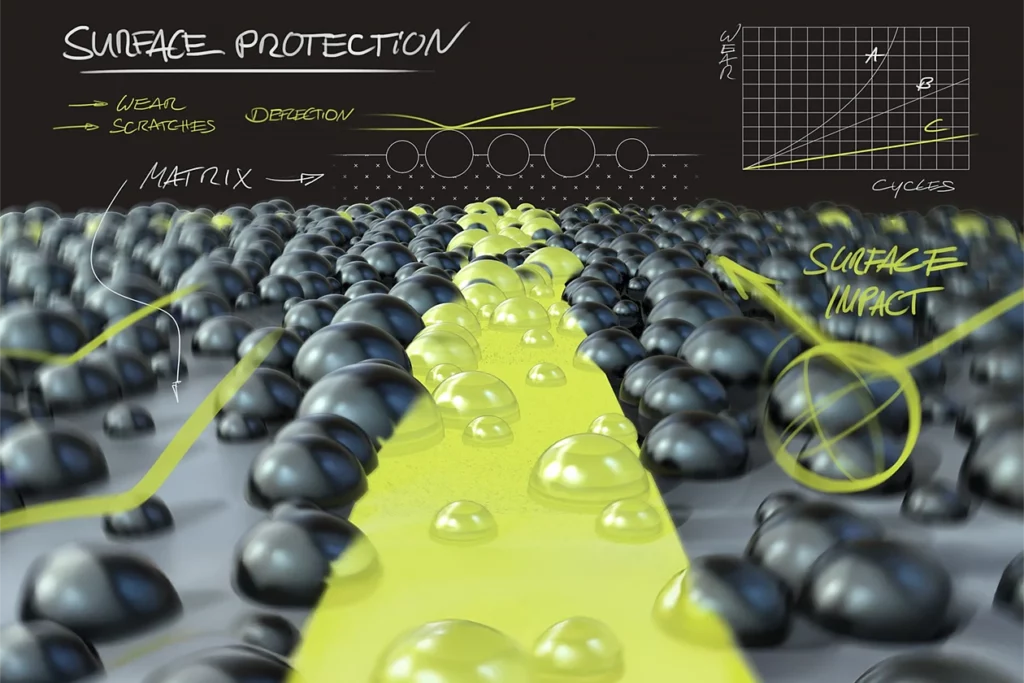

Their use increases rigidity, pressure and scratch resistance. In addition, the beads improve flowability, reduce warpage and shrinkage, and give the final product uniform coloration, brilliant surface gloss, and optimal light diffusion.

Areas of application

Glass filler beads in paints, varnishes and coatings

Glass filler beads are used in paints, varnishes and coatings to enhance different physical properties of glass, for example to improve the surface and scratch resistance. In laminate flooring, glass filler beads reinforce the overlay, increasing abrasion resistance.

Glass filler beads for plastics

Glass filler beads are added to the materials used for compounding/processing plastic granulate in order to enhance the required qualities. In injection moulding materials, glass filler beads reduce warpage and shrinkage thanks to their isotropy. They are typically used in technical components, interior and exterior automotive parts, and 3D printed materials.

Glass filler beads for building materials

In the building materials industry, glass filler beads are used, among others, in translucent joint sealants, which break light in addition to reflecting it. This enhances the colours of glass mosaics and glass tiles and gives them a shimmering effect. Surface structures compacted with SWARCOFORCE glass filler beads are waterproof and easy to clean.

Glass filler beads in the additive manufacturing of plastics

In the additive manufacturing of plastics, SWARCOFORCE glass filler beads from SWARCO Indusferica optimize the material’s properties. As a filler and reinforcing material, they are used in particular in selective laser sintering (SLS) and fused deposition modelling (FDM) manufacturing processes.

Glass beads with a small carbon footprint

At a time when sustainability and environmental protection are becoming increasingly important, companies are called on to find innovative solutions that both improve the performance of their products and minimize any adverse environmental impact. With its innovative glass beads for special industry applications, SWARCO Indusferica is showing the way.

Technical data

The glass filler beads are made from soda-lime glass cullet.

Foreign impurities are permissible only up to a max. of 0.1 percent by weight.

Specific weight

Bulk weight

Roundness

Mohs hardness

Rockwell hardness

Vickers hardness

Chemical composition

Sievings and applications

SWARCO Indusferica is your competent partner for tailor-made solutions using micro glass beads as fillers in industrial applications. Many different grain sizes are available, and the production process narrow tolerance ranges. Further customized particle-size distributions are possible upon request.

Silanization

SWARCOFORCE glass filler beads can be used with a wide variety of coatings, which defines the interaction between the glass and the matrix material used (e.g. the adhesion between glass and plastic).

Recommended silane type

Embedding material/Matrix material

Thermosets/

Elastomers

- Polyester

Thermoplastics

- Acrylic resin, unsaturated

- Polyethylene (PE)

- Polypropylene (PP)

Thermosets/

Elastomers

- Epoxy

- Melamine

- Polyurethane (PU)

Thermoplastics

- Acrylonitrile butadiene styrene (ABS)

- Polybutylene terephthalate (PBT)

- Polystyrene (PS)

Thermosets/

Elastomers

- Epoxy

- Melamine

- Polyurethane (PU)

- Silicone

Thermoplastics

- Acrylic resin, unsaturated

- Polyamide (PA)

- Polybutylene terephthalate (PBT)

- Polycarbonate (PC)

- Polyethersulfone (PESU)

- Polymethylmethacrylate (PMMA)

- Polyoxymethylene (POM)

- Polystyrene (PS)

- Polysulfone (PSU)

- Polyvinyl chloride (PVC)

- Styrene acrylonitrile (SAN)

- Thermoplastic polyurethane (TPU)

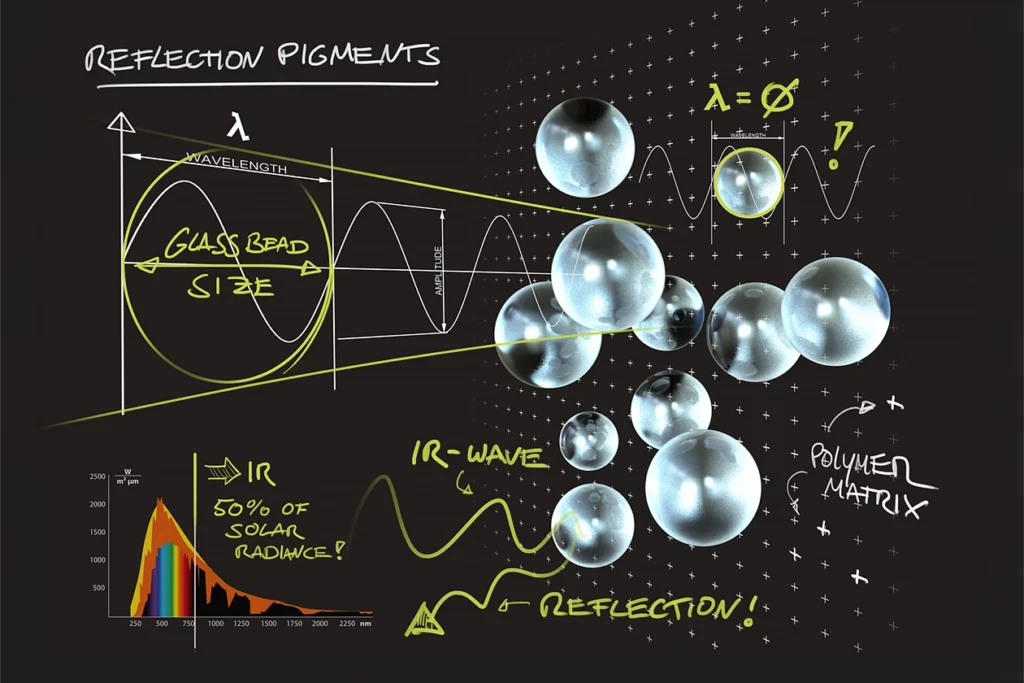

SWARCOFORCE REFLEX

Glass filler beads with a high refractive index

SWARCOFORCE REFLEX glass filler beads enhance plastics

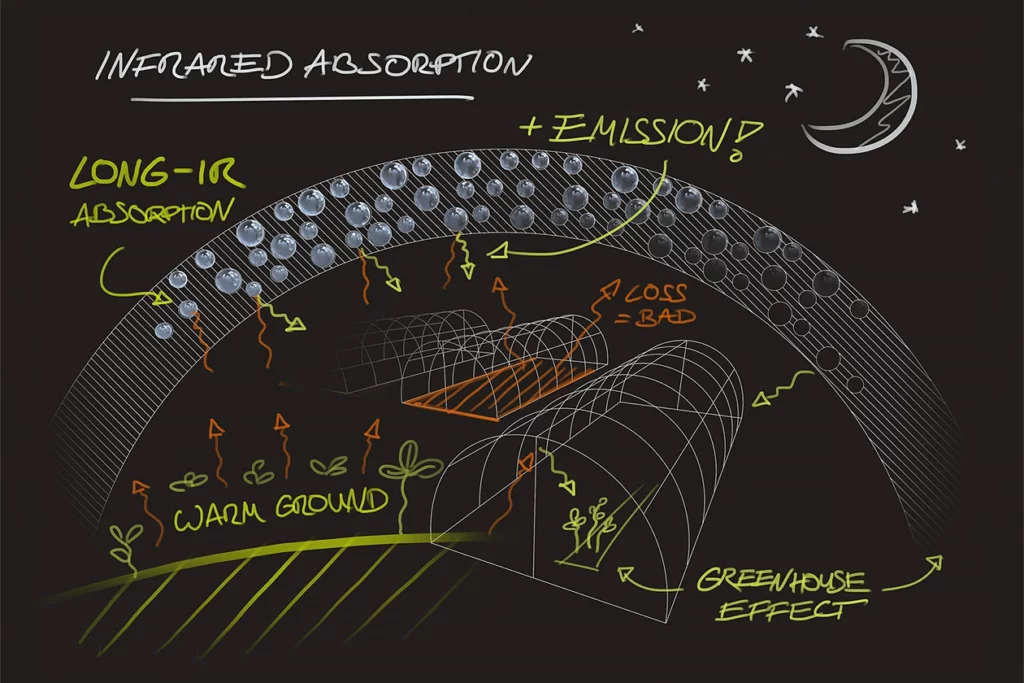

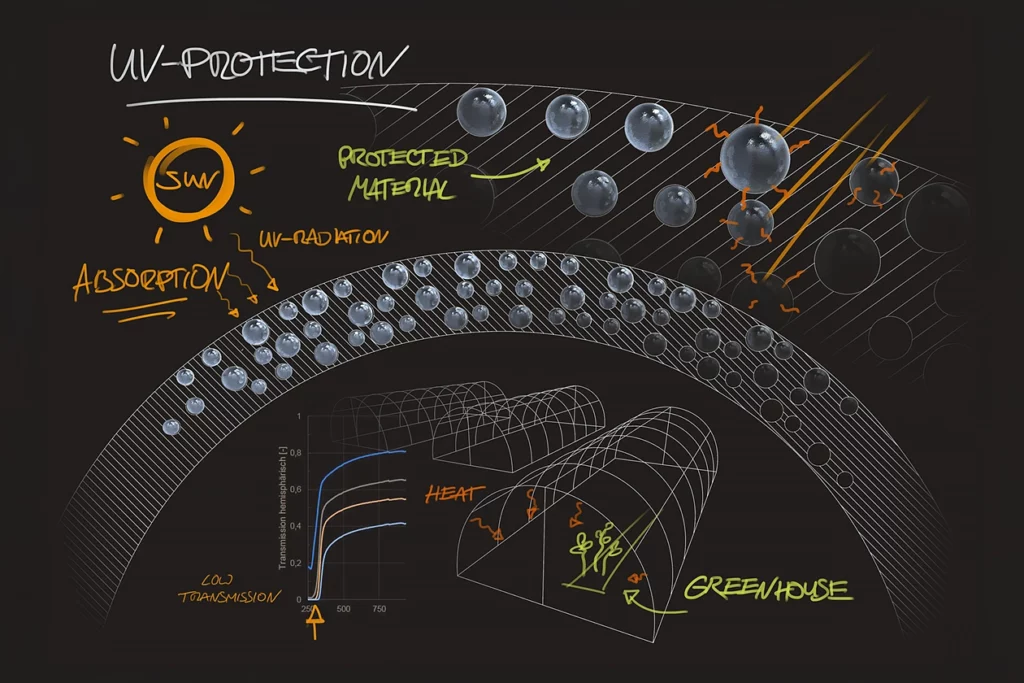

SWARCOFORCE REFLEX glass filler beads have a high refractive index. They are added in the processing of plastic films and multi-wall sheets in order to enhance the plastic’s qualities. In greenhouses, for example, this can prevent overheating during the day and reduce heat loss at night.

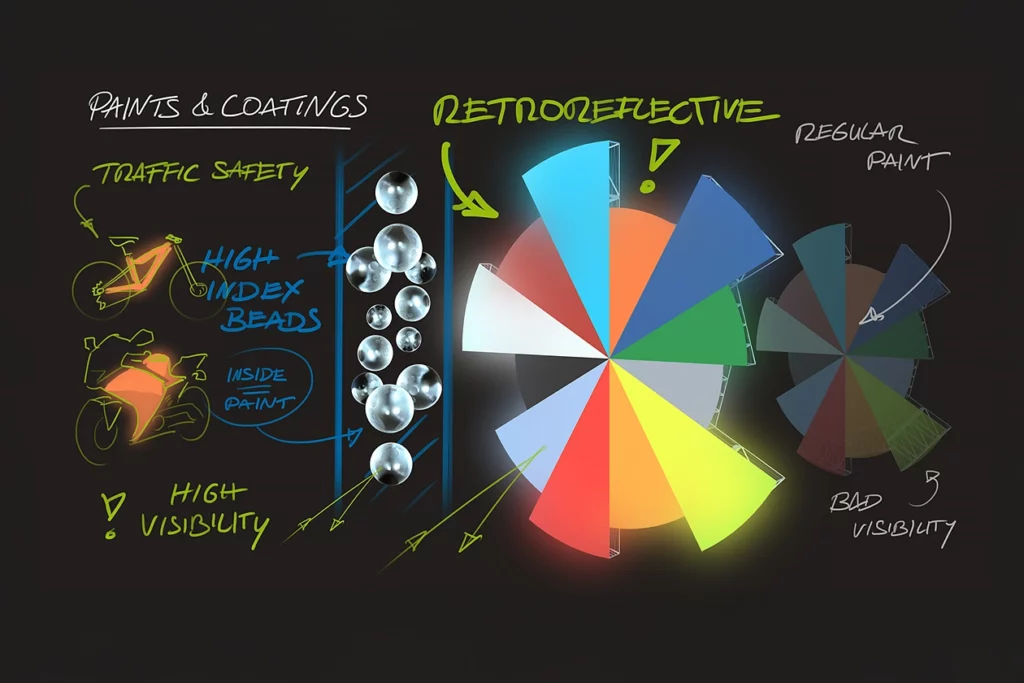

SWARCOFORCE REFLEX glass filler beads optimize paints, varnishes and coatings

In paints, varnishes and coatings, SWARCOFORCE REFLEX glass filler beads are used to improve surface properties, such as scratch and abrasion resistance. The increased retroreflection achieved by using glass filler beads with a high refractive index also enhances optical effects of paints and varnishes.

Properties

Glass filler beads absorb long-wave infrared radiation and re-emit this energy back to their environment.

UV radiation is absorbed by glass filler beads, reducing polymer degradation and the formation of fungi on greenhouse films.

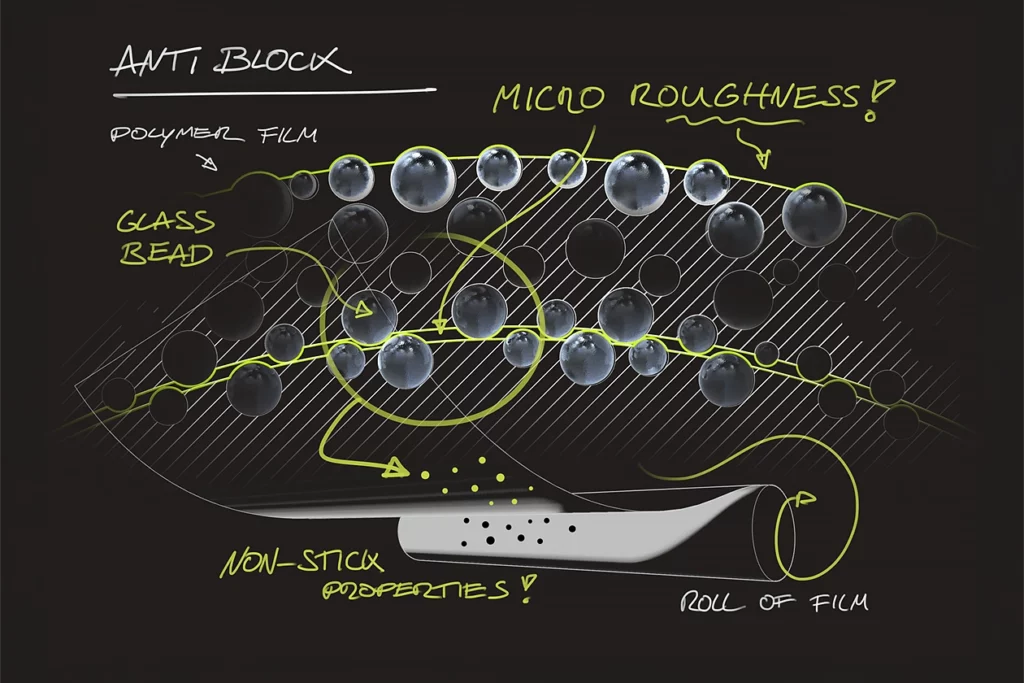

With glass filler beads, it is possible to obtain a certain micro-roughness of the film surface, and thus, prevent blocking in rolls.

Many applications benefit from the increased retroreflection of paints, varnishes and coatings achieved by using glass filler beads with a high refractive index.

High reflection of glass filler beads with a high refractive index in the NIR band allows for excellent results in heat-reflective and optical applications.

Glass filler beads increase scratch and abrasion resistance of product surfaces.

Technical data

SWARCOFORCE REFLEX glass filler beads are made of barium titanate glass.

Foreign impurities are permissible only up to a max. of 0.1 percent by weight.

REFLEX21

Retroreflective index

Specific weight

Bulk weight

Roundness

Sievings and applications

Many different grain sizes are available, and the production process ensures narrow tolerance ranges. Further customized particle-size distributions are possible upon request.

PDS SWARCOFORCE 1-20

PDS SWARCOFORCE 1-20 C1

PDS SWARCOFORCE 1-20 C2

PDS SWARCOFORCE 1-20 C3

PDS SWARCOFORCE 1-50 Typ 1 C2

PDS SWARCOFORCE 1-50 Typ 1 C1

PDS SWARCOFORCE 1-50 Typ 1

PDS SWARCOFORCE 1-50 Typ 1 C3

PDS SWARCOFORCE 1-50 Typ 2 C1

PDS SWARCOFORCE 1-50 Typ 2

PDS SWARCOFORCE 1-50 Typ 2 C2

PDS SWARCOFORCE 1-50 Typ 2 C3

PDS SWARCOFORCE 40-70 C3

PDS SWARCOFORCE 40-70 C2

PDS SWARCOFORCE 40-70 C1

PDS SWARCOFORCE 40-70

PDS SWARCOFORCE 63-250

PDS SWARCOFORCE 63-250 C1

PDS SWARCOFORCE 63-250 C2

PDS SWARCOFORCE 63-250 C3

PDS SWARCOFORCE 70-110

PDS SWARCOFORCE 70-110 C1

PDS SWARCOFORCE 70-110 C2

PDS SWARCOFORCE 70-110 C3

PDS SWARCOFORCE 90-150 C2

PDS SWARCOFORCE 90-150 C1

PDS SWARCOFORCE 90-150

PDS SWARCOFORCE 90-150 C3

SWARCOFORCE Brochure

SWARCOFORCE Flyer

SWARCOFORCE Technical Information

SWARCOFORCE REFLEX Flyer

SWARCOFORCE REFLEX Technical Information

Sustainability & responsibility

At SWARCO, corporate responsibility to the environment and society plays an important role. That’s also why we take numerous steps to reduce our ecological footprint.

Glass beads with a small carbon footprint

Setting new standards in environmental compatibility

Cradle-to-Gate

An efficient circular economy

Contact us

We strive to offer our customers tailor-made solutions to meet their specific needs.

Thomas Auinger

Head of SWARCO Indusferica